Sustainable production for a green future - CO2-neutral thermal energy without compromising!

With our consulting services and solutions, you're not only able to maintain your competitiveness, but also to make a valuable contribution to environmental protection by ensuring a climate-friendly and sustainable production.

ANALYSIS

CONSULTATION

OPTIMISATION

SPEAKING

As process engineers, we appreciate the challenge, and as family fathers, we feel responsible for driving the energy transition. Both are our motivation. How can we contribute?

We do what we do best and have been doing together for decades:

creating really good combustion.

Whether fuels are in gas, liquid, or dust form doesn't matter. Our goal is to develop the most efficient solution with the lowest CO2 footprint and to support it until implementation. We advise on making combustion processes cleaner, more efficient, flexible, and robust. We do so fairly, reliably, and measurably.

We are Sven, Philipp, and Ronald. We are Ombustion. Taking the C out.

Dipl.-Ing. Philipp Schönberger

Partner

Dipl.-Ing. Sven Gose

Partner

Dr.-Ing. Ronald Wilhelm

Partner

OUR CUSTOMERS

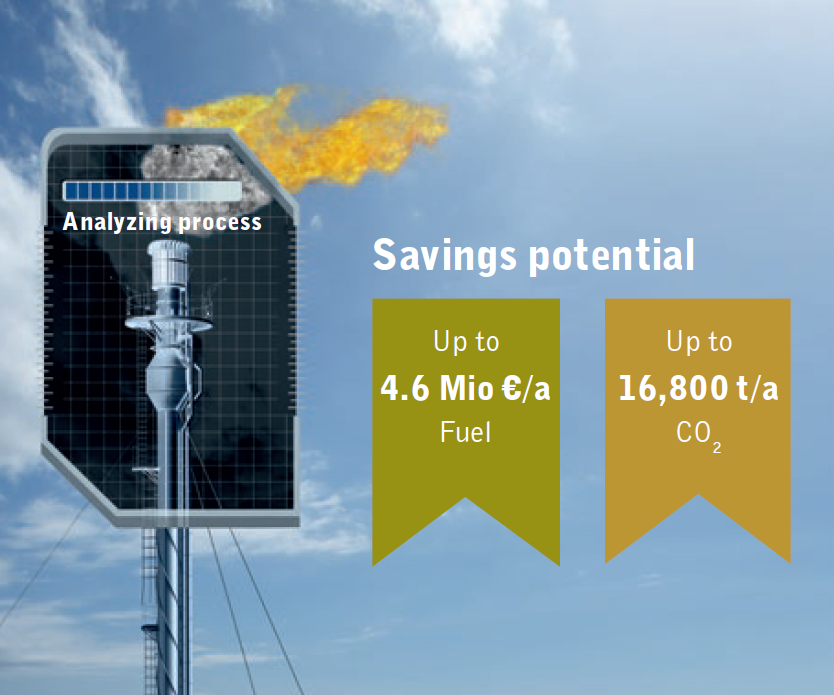

ANALYSIS

Capture the energy requirements of your business and optimize the choice of fuel for maximum efficiency and sustainability.

CONSULTING & OPTIMISATION

Efficient and Zero Emissions: Expert advice for transitioning to alternative fuels and optimizing combustion processes.

CUSTOMER FEEDBACK

The Consulting and Engineering (OMBUSTION) department of Bremen-based SAACKE GmbH was commissioned to investigate the combustion-related effects of this changeover in the form of a simulation as part of a planned fuel changeover on a water tube boiler.

Once the order had been placed and the previously agreed as-built documentation had been submitted, work on the project began immediately. The project was always carried out in close coordination with the client, but largely independently and under the responsibility of the project management.

As a customer, we always felt very well informed and were very satisfied with both the project process and the presentation of the results and can recommend SAACKE (OMBUSTION) as a contractor without reservation.

CUSTOMER FEEDBACK

In addition to the long-standing use of hydrogen as an energy source in intralogistics, the aim at the BMW Group plant in Leipzig is to use green hydrogen in future as a substitute for fossil natural gas in the process heat of the paint shop.

Saacke (OMBUSTION) took up this challenge with great enthusiasm and developed fuel-flexible methane/hydrogen burners that can be easily integrated into the existing structure.

This technology makes it possible to fulfil emission requirements in the medium term and at the same time be ready for a future with hydrogen as an energy source.

It is a great pleasure to work in partnership with the engineers at Saacke as a driver of innovation.

OUR CUSTOMERS

After a joint project, you are familiar with the levers for an efficient and possibly CO2-neutral production, can calculate your future operating costs and know the investment and time requirements for your future-proof energy generation.

At a minimum, we have optimized your existing system and provided you with valuable hints for more efficient and environmentally friendly operation.

How can we help you?

Click on the button now and arrange a free call...